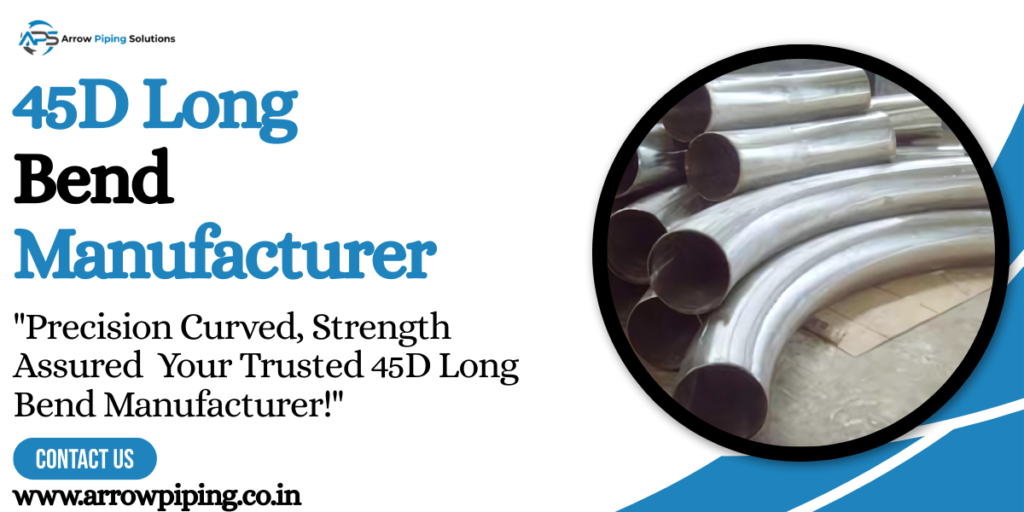

45D Long Bend Manufacturer

Table of Contents

Introduction

Arrow Piping Solutions, founded in Kalbadevi, Mumbai, Maharashtra, is a prominent name in the industrial sector, offering a wide range of high-quality industrial products that cater to diverse industries across the globe. Established with a vision to provide top-notch products and exceptional services, we specialize in the manufacturing, stocking, importing, and exporting of a comprehensive range of products, including Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Unions, Valves, Gaskets, Pipes & Tubes, Sheets, Plates, Coils, Bars, and Structural Steel Products.

Have you ever wondered how the gasses or fluids manage to flow through such a complicated system of pipes? Well, pipe bends—the unsung heroes of the plumbing industry—are responsible for a significant portion of that smooth flow. Additionally, the 45D long bend frequently takes center stage when it comes to effective, gentle redirection.Although “45D long bend” may sound like scientific jargon, let’s simplify it. Consider a pipe that needs to make a 45-degree turn. Sometimes a more gradual curve is required to reduce friction and pressure drop in the system, although a standard elbow could work just fine. The “long bend” enters the picture at this point. We are the best 45D Long Bend Supplier.

What Exactly is a 45D Long Bend

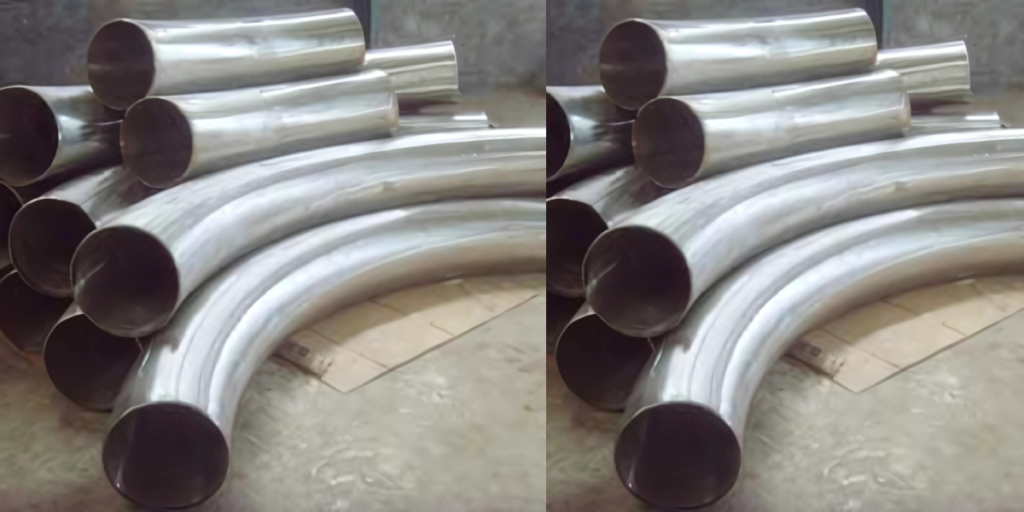

Let’s dissect it. A “bend” in a pipeline is a portion that is curved to alter the flow’s direction that is being discussed. The radius of curvature of this bend is indicated by the “45D” portion of the name. Here, the “D” stands for the pipe’s nominal diameter. We are the best 45D Long Bend Stockist.

Therefore, the radius of a 45D long bend is 45 times the diameter of the pipe for which it is intended.What’s the “long” part now? This sets it apart from bends with “short” radiuses. In contrast to a short radius bend, which usually has a radius of 1D or 1.5D, a long radius bend, such as our 45D variant, has a softer curve. Its greater performance is mostly due to its longer radius.

Why Choose Arrow Piping Solutions

- Unwavering Quality: Throughout the manufacturing process, we use strict quality control procedures and only use premium-grade raw materials. We guarantee that every 45D Long Bend that leaves our facility is constructed to last and operate faultlessly, starting with the initial material inspection and ending with the final dimensional inspections.

- Precision Manufacturing: We guarantee accurate measurements and constant curvature in every bend thanks to our cutting-edge manufacturing machinery and knowledgeable personnel. Long-term dependability, ideal flow characteristics, and simpler installation are all correlated with this accuracy.Broad Variety of Materials and Specifications: We are aware that the needs of various applications vary. To meet your unique needs, we provide 45D Long Bends in a range of materials, such as alloy steel, carbon steel, and stainless steel. Additionally, we are able to produce bends in accordance with a range of industry norms and requirements.

- Customization Features: Have a special need? Together, you and our skilled engineering staff may create unique 45D Long Bends that meet the requirements of your particular project. We are aware that there are situations where one size does not fit everyone.

- Competitive Pricing: We are dedicated to providing competitive pricing to provide you the most return on your investment, without sacrificing quality. High-quality pipe fittings shouldn’t be prohibitively expensive, in our opinion.

- On-time Delivery: We recognize how crucial it is to follow project schedules. Our strong logistics network and effective production procedures guarantee that you receive your 45D Long Bends on schedule, reducing delays and maintaining project momentum.

- Superb Customer Service: At Arrow Piping Solutions, we value establishing enduring bonds with our customers. Our committed customer service team is available at all times to answer your questions, offer technical advice, and guarantee a hassle-free and easy experience. We are a partner who cares about your success, not just a supplier.

- Industry Knowledge: Our staff has years of experience in the pipe sector, giving them the knowledge and skills necessary to comprehend your unique application and suggest the best solutions. To give you state-of-the-art goods and services, we keep abreast of the most recent developments and trends in the industry.

- Dedication to Innovation: To enhance our production procedures and broaden our range of products, we consistently engage in research and development. Our objective is to supply you with cutting-edge and effective pipe solutions that satisfy the changing needs of your sector.

Benefits of 45D Long Bend

- Decreased Friction and Pressure Drop: The pipe’s turbulence is reduced by the soft curvature. This results in a reduced pressure drop across the bend since there is less flow resistance. Long-term energy savings can result from this since pumps don’t have to exert as much force to move the fluid.

- Reduced Wear and Tear: When using abrasive materials, sharp bends can cause the fluid or gas to slam against the pipe wall, which over time can cause erosion and corrosion. The piping system’s lifespan is increased by the lengthy bend’s gentle curvature, which more equally distributes the load.

- Increased Flow Efficiency: A lengthy curve promotes a smoother flow, which increases the system’s overall efficiency. In sectors where steady and regular flow rates are critical, this is vital.

- Reduced Noise and Vibration: Noise and vibrations produced by turbulent flow in acute bends can be annoying and even harmful to nearby equipment. A system with long bends is more stable and quiet.

- Easier Pigging Operations: “pigging” is a typical maintenance procedure in many pipelines, particularly those that carry gas and oil. Pigs are tools that are put into the pipeline to clean, check, or even segregate various products. These pigs find it much easier to navigate long bends without becoming stuck because of their soft curves.

- Improved System Efficiency: By reducing friction and turbulence, our carefully designed long bends increase flow rates and lower energy usage.

- Longer System Lifespan: Our bends’ gentle curves lessen the strain and deterioration on your pipes, extending their useful life and lowering replacement expenses.

- Lower Maintenance Costs: Our bends assist avoid leaks and failures by reducing wear and turbulence, which lowers maintenance needs and downtime.

- Increased Safety and Reliability: Your piping systems will be safer and more reliable overall because of our dedication to quality, which guarantees that our bends satisfy strict industry requirements.

Table of Specifications 45D Long Bend

| Specification | Details |

|---|---|

| Product | 45D Long Radius Bend |

| Angle | 45 Degrees |

| Radius | 1.5D to 10D (custom available) |

| Sizes Available | ½” NB to 48” NB |

| Material Grades | SS304, SS316, Carbon Steel, Alloy Steel, etc. |

| Standard | ASME B16.9, ASTM A234, ANSI, DIN, JIS |

| Wall Thickness (Schedule) | SCH 10 to SCH XXS |

| Surface Finish | Black, Galvanized, Pickled, Passivated |

| End Connections | Beveled / Plain / Flanged Ends |

| Testing | Hydro Test, NDT, PMI, UT |

| Applications | Oil & Gas, Water Supply, Chemicals, Power Plants |

| Country of Origin | India |

| Manufacturer | Arrow Piping Solutions |

Applications of 45D Long Bends

- Oil and Gas: These bends reduce friction and energy loss over long distances in pipelines carrying natural gas or crude oil. Additionally, they lessen the possibility of turbulence harming the pipeline or lowering the caliber of the substance being conveyed.

- Chemical Processing: Transferring caustic or sensitive fluids is a common step in many chemical processes. Consistent processing and material damage prevention are ensured by the smooth flow that 45D long bends give.

- Power Generation: These bends are utilized in a variety of piping systems in power plants, such as those that transport cooling water or steam. Their design lessens the strain on the pipes and maintains an efficient flow.

- Food and Beverage: In the food and beverage sector, maintaining cleanliness and avoiding contamination are crucial. 45D long bends’ flat inside surface reduces the possibility of material accumulation and facilitates cleaning.

- Pharmaceuticals: The production of pharmaceuticals necessitates strict adherence to hygiene standards and regulated flow, much like the food and beverage sector. Bends with a long radius are crucial for maintaining the integrity of pharmaceutical items.

- Water Treatment and Distribution: Reducing pressure loss is essential to the effective functioning of large-scale water treatment facilities and distribution systems. This efficiency is enhanced by 45D long bends.

- HVAC Systems: Long radius bends are frequently used in large commercial and industrial HVAC systems to maximize fluid and air flow inside the system and increase energy efficiency.

Types of 45D Long Bend

- Bends with a radius equal to the nominal pipe diameter (1D bends) are known as 90 degree short radius bends, as opposed to long radius bends. They are appropriate for spaces with limited space because they provide a more compact option for 90-degree turns. In contrast to long radius bends, they typically cause a greater pressure drop and more turbulence.

- 180 Degree Return Bends: These bends cause the pipeline to make a 180-degree U-shape. Boilers, heat exchangers, and other devices where fluids must return in the opposite way frequently employ them. Both long and short radius return bend variants are available.

- Tees: To form a 90-degree branch from the main pipeline, pipe tees are fittings. They are crucial elements for allocating flow to various system components. Tees come in a variety of shapes, such as decreasing tees, which have a branch with a smaller diameter than the main line, and equal tees, which have three branches with the same diameter.

- Like tees, laterals (Wyes) form a branch from the main pipeline, but they do so at an angle other than 90 degrees, usually 45 degrees. Compared to tees, laterals provide a smoother flow transition, lowering pressure drop and friction in the branch line.

- Reducers: In a plumbing system, reducers are fittings that progressively increase or decrease pipe diameter. They are essential for maintaining the appropriate flow velocity and joining pipes of various sizes. There are two primary types of reducers: eccentric (for pipes with offset centerlines) and concentric (for pipes with a common centerline).

- Pipe caps and closures: These items are used to seal the ends of fittings or pipes. Closures can be welded or threaded to the interior of the pipe, whereas caps usually fit over the outside. They are crucial for stopping leaks and separating pipeline segments for upkeep or future growth.

Conclusion

The seemingly straightforward 45D long bend is essential to the safe and effective movement of fluids in a variety of industries. Compared to harsher bends, its mild curvature has several advantages, including smoother flow, lower energy usage, and a longer system lifespan. We are the best 45D Long Bend Dealer.

It’s crucial to pick the correct manufacturer for these vital parts, and Arrow Piping Solutions is prepared to be your reliable partner. You will receive excellent 45D long bends that satisfy the highest requirements thanks to our unwavering commitment to quality, our vast expertise, and our passion to customer satisfaction.